Beach Disposal Prototype 2.0

I mastered the thread on this model and the screw-on effect is much smoother. I want to add a loop on the side for my next print, so that I can attach it to my bag with a caribener.

My hydroflask didn't fit into my car's cupholders, so I designed and 3D-printed a water bottle adapter for my car's cupholders and hydroflask size. This is my favorite project so far because it's become a functional part of my everyday life.

I mastered the thread on this model and the screw-on effect is much smoother. I want to add a loop on the side for my next print, so that I can attach it to my bag with a caribener.

My first time trying the wooden lathe. I practiced using different kind of tool shapes and testing on some scrap wood I found. Overall, came out well and I'd love to use this machine more.

I fully modeled these boomeranags myself, and I plan on sanding the complete one when I have time. But the CNC messed up and the bit fell out runining the cut out for one of the boomerangs. Still cool to see my models come to life.

I completely modeled this myself, and it took around 3 tries to print the threading to work correctly. I'm happy with how this turned out, the hooks work to keep fishing string in and the pocket is for hooks. I'll use this to cleanup spots I'm fishing at and help the environment.

I tried lasering a wooden box out, but the tolerances came out wrong so the pieces didn't fit completely. I will come back and try to laser something that properly fits next time, but it was good practice.

This project combined two other projects to create neat room art. I cleaned up trout plasma cut with grinder and sprayed coating. Used T-Weld to create a stand for the trout cut-out.

After freehand-sketching a model on Fusion, I CNCed these fishing rod holders. I then use the roter to curve the edges for a nicer finish.

After gaining some confidence with MIG welding, I attempted to make an art piece out of scrap metal where I use multiple weld angles. I sand blasted and grinded the scrap metal.

After some practice with MIG welding, tried doing a T-Weld to create a miniature stand for other projects. Welds came out well and strong.

First time MIG welding on 16 gauge steel. Practiced using a swirling technique and correct speed/distance to create useful beads.

This project involved translating a 2D image into a vector-based sketch using Fusion 360. The design was then programmed via CAM to control a plasma cutter, resulting in a precise metal art piece. It showcases skills in digital design, manufacturing processes, and machine operation.

CADed 3D printed Flywheel used as a large scale model of future prototypes for engines and other projects.

A practical project to organize and display surfboards. Designed and installed custom wall-mounted holders using hand-tools.

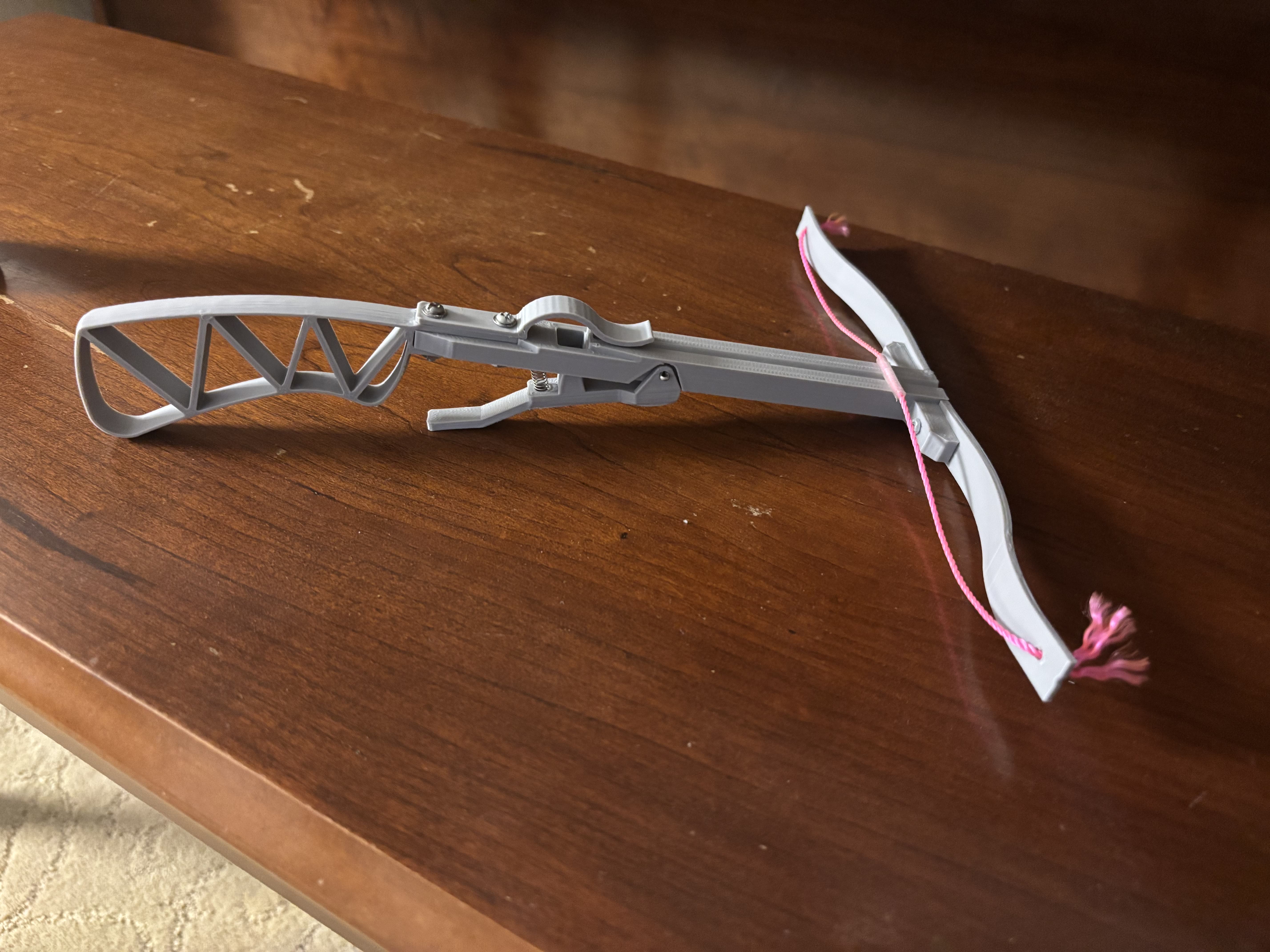

An interactive 3D print that incorporates spring mechanics and string tension to create a functional, projectile-launching model.

Created a 3D printed replica of a video game knife, featuring a synthetic rope handle wrap for an authentic look and feel.

An intermediate, multi-part 3D print designed with articulated joints to allow for realistic, snake-like movement.

Our first project using a Creality 3D printer. A quick and simple print to learn the basics of slicing and machine operation.

A cheap and effective solution to keep fishing rods out of the sand and water at the beach, constructed from PVC pipes.

We're brothers and students passionate about engineering, using this platform to document our growth and journey in the field. We are constantly learning and applying skills in CAD, CAM, 3D Printing, programming, and hands-on fabrication.